Sponsored Content Brought To You By Alure Home Improvements

There are various reasons why the Sheetrock in your home can end up with a big, unsightly hole: a stubborn nail that once balanced a picture took out a decent chunk when it collapsed; clumsy movers bumped a dresser into the wall while attempting to transport it to your bedroom; the doorknob to your bathroom struck it one too many times.

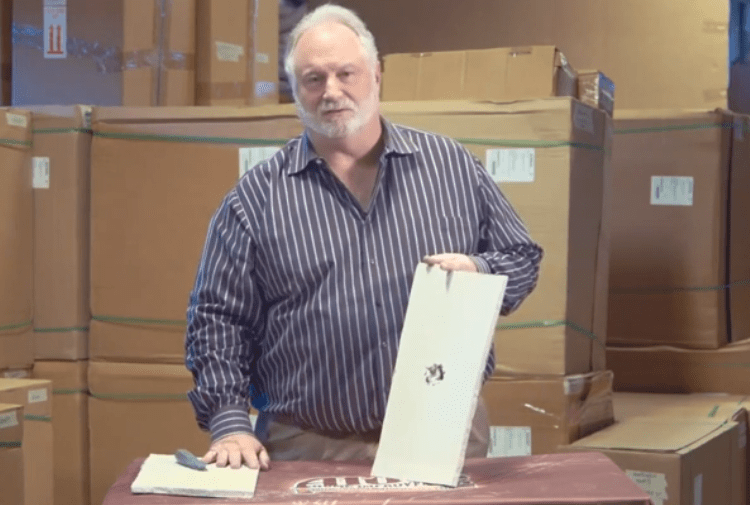

Here Doug Cornwell, chief operating officer of Alure Home Improvements, demonstrates that once again he’s got us covered when it comes to home repairs that can be handled easily and speedily. In this recent installment of Alure Home Improvement’s “60 Second Fix,” he demonstrates how to fix a hole in Sheetrock.

“I’m going to show you a very quick and very inexpensive way to do it, especially if you have a few pieces of leftover Sheetrock lying around,” says Cornwell.

In this example, the offensive orifice is about the size of a doorknob, or, tellingly, a baseball.

“It could be anything that went through the Sheetrock,” Cornwell observes.

We’ll never know the culprit in this example but that’s not important because the solution is readily at hand.

First, he says you want to square the space around the cavity. You don’t want to leave it as it is. He takes a box-cutter utility and makes a rectangular incision that encompasses the hole. Then he takes the handle of the knife and gently taps the Sheetrock square loose so the unwanted material can be removed. Sometimes you may have to trim the edges in case any uneven layers remain.

Next, you take the replacement Sheetrock from your leftover supply. He says that it doesn’t even have to be the same thickness since Sheetrock panels can vary in width. “This is one instance where size doesn’t matter!” he says.

“You want to make a cut that’s going to leave about two inches overlap on each side,” Cornwell says. “Make your first line. Then turn it over, snap it and cut it.”

Rotate the patch 90 degrees and measure the perpendicular edge so you have the proper overlap margin. Make a line with your knife, score the line, cut it and snap it.

“It doesn’t have to be perfect,” he says. But he emphasizes that the edges should look even.

You do that for each edge of the patch. You’ll use tape and joint compound to make the patch match smoothly.

Click here to learn more about Alure Home Improvements

That’s phase one for the front side of the patch. The next step is to trim the back side so you can get it to fit right into the hole.

Cornwell shows how you line up each side of the patch, score the line with the knife, and then rotate the patch 90 degrees so you can repeat the same procedure. What he emphasizes is to make the back side of the patch slightly less than the dimensions of the hole you previously squared so the new patch will fit into the hole comfortably.

You work on the back side of the Sheetrock patch so that you can carefully peel the gypsum material away without tearing the front paper layer. The front surface of the patch is intended to be larger than the squared hole’s edges so you can apply the joint compound around the hole to glue it in place, as he shows you. When the patch is ready to go into the hole, spread the joint compound around the margins of the squared hole so the paper will stick to it. Once you’ve smoothed it out, you can apply Spackle over the edges to hide the seams.

“All you’re trying to do is flush up the front surfaces,” Cornwell advises. “Once you get the knack of it, it goes pretty quick.”

You’re on your way to becoming an expert Sheetrocker!