After months of public hearings and more than a year of odor complaints from nearby residents, the Port Washington North Board of Trustees voted Tuesday night, Feb. 10, to allow Bombay Kitchen, a food processing business at 85 Channel Drive, to continue limited operations at 50 % capacity through Feb. 28, after which all cooking and frying must cease.

The decision came at the close of a lengthy public hearing that began in August and was continued multiple times as village officials and the applicant debated whether odors from the facility could be eliminated in compliance with the village code.

Bombay Kitchen, operated by Ethnic Foods Inc. and owned by Sanjiv Mody, has held a conditional use permit since 2019 to operate a food processing and manufacturing business in the village’s Economic Development B zoning district.

Under village code, such uses are permitted only by conditional approval and are expressly prohibited from generating any odor because of the district’s proximity to residential properties.

While earlier permit renewals had not drawn significant concern, trustees said that odor complaints began following the 2024 renewal, when the company introduced new fried products. Residents reported pervasive, unpleasant smells, prompting site visits by village officials and enforcement actions, including a cease-and-desist order.

At Tuesday’s meeting, the board grappled with whether to grant the applicant additional time to relocate cooking operations outside the village while continuing some level of production at the site.

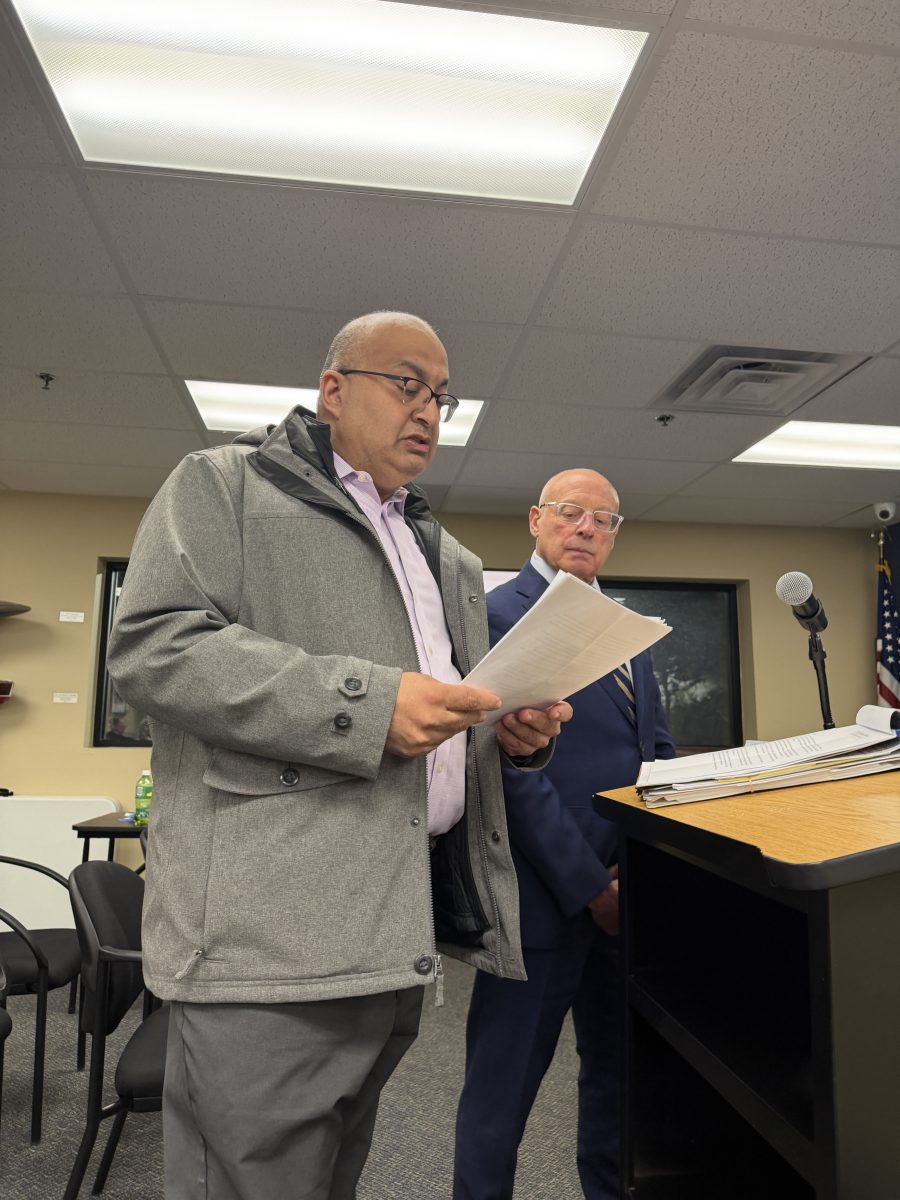

Attorney Michael Sahn, representing the applicant, told trustees that the company has decided to relocate its frying and food processing operations to another jurisdiction and has been searching for a new facility since December.

“We have made a decision to relocate,” he said, adding that the company hopes to continue operating at reduced capacity while securing a new site. He acknowledged that despite installing an expensive air filtration system known as a “captive air” scrubber, the odors have not been completely eliminated.

“The system has turned out not to be 100 % perfect,” he said. “It is a big and substantial improvement, but there have still been some instances, admittedly, of some detectable odor.”

According to the applicant, production had already been cut roughly in half, with only one of two production lines in operation and the discontinuation of certain fried items, including falafel. The company said it is currently producing a single “crunch” product and has ceased other items identified as odor sources.

Sahn told the board that the business had invested more than $100,000 in odor mitigation equipment and had worked with engineers and the village building department to adjust filtration and operational settings.

“We’ve installed the system as we agreed to,” Sahn said. “We’ve made changes. The odors have been minimized substantially, but it’s not zero.”

Mody asked the board for time to “wrap up peacefully” with employees and customers, noting that the company has purchase orders and raw materials on hand.

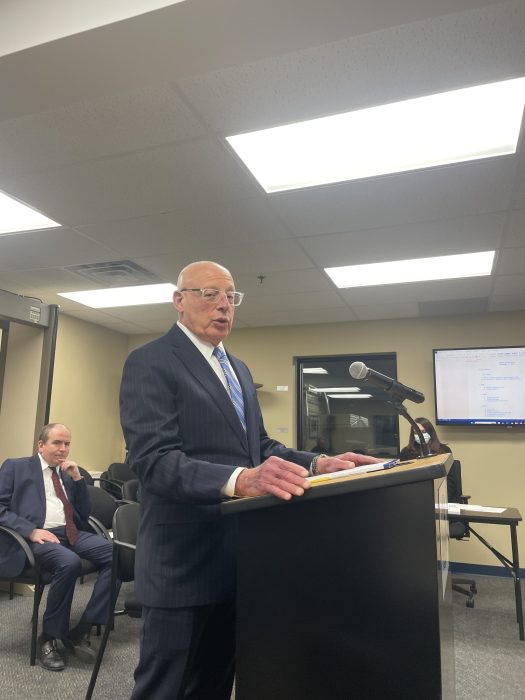

Trustees repeatedly returned to the language of the village code, which prohibits any use that generates odor in the zoning district. Several board members said that while they appreciated the applicant’s efforts, the issue had not been resolved.

“The problem still has not been solved,” Trustee Matthew Kepke said. “We haven’t gotten rid of the problem.”

He said the board had previously requested expert testimony on the environmental and health impacts of the odors and that the applicant had presented only a mechanical engineer’s opinion, without additional environmental analysis.

“We were told this system would eliminate all the odors,” Kepke said. “Now we’re being told it can’t.”

Village officials confirmed that although the odors had been “substantially minimized,” they remained detectable. The building department has periodically lifted a cease-and-desist order to allow limited cooking strictly for testing and calibration of the new filtration equipment.

Superintendent of Buildings Robert Barbach told the board that those accommodations were intended to allow the applicant to refine the system, not to resume full production. He also clarified that only the cooking and frying operations were the source of the odor complaints; yogurt production, packaging, storage and distribution operations had not generated issues.

Trustees expressed concern that allowing production to continue for several more months would expose nearby residents to additional odor impacts, particularly as warmer weather approaches and residents spend more time outdoors.

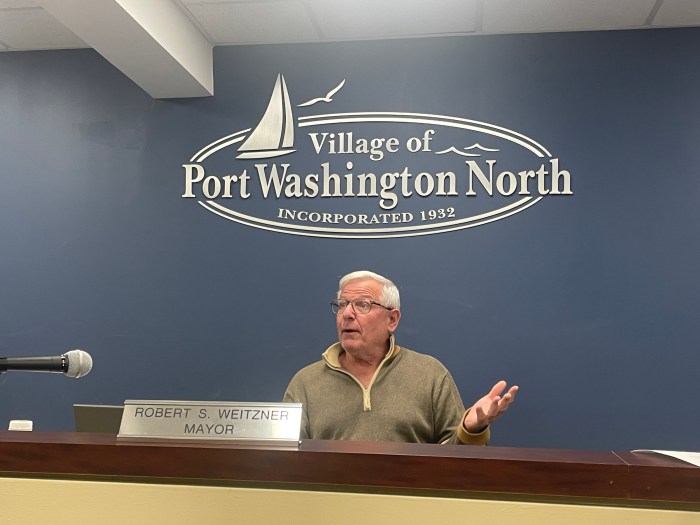

“If this were June or July, I think the answer would be to shut it down immediately,” Mayor Robert Weitzner said.

The board debated several possible end dates for cooking operations, including immediate termination, a two-week wind-down period, or allowing operations to continue until the next board meeting on March 10.

Mody initially indicated that the company had sufficient raw materials to continue production into April and sought additional time to fulfill customer commitments. That statement drew pushback from trustees who said the business had been aware of the ongoing enforcement issues and should not expect to continue production indefinitely.

“You had full intention of trying to get as many orders as you can,” Kepke said, adding that the board’s willingness to consider a short extension was based on economic impact to employees and customers, not on approval of continued production.

Ultimately, trustees agreed to a compromise: allowing the company to continue operating one production line at its current reduced level — described as roughly 50 percent capacity — through Feb. 28, with strict conditions.

The board required that only one production line may operate at 50% capacity, no increase in production beyond current levels is permitted, the company must provide the building department with a detailed production schedule by Feb. 11, and the building department retains the right to inspect the premises during operating hours.

From March 1 until the board’s March 10 meeting, no cooking or frying will be permitted. Only yogurt production, packaging, storage and distribution may continue.

Trustees emphasized that any violation of the production limits or schedule could result in immediate enforcement action.

“This is not a free pass,” Weitzner said. “If there is any deviation, the building department has the authority to act.”

The board formally closed the public hearing Tuesday night and directed the village attorney to prepare a draft resolution reflecting the board’s intent to extend the conditional use permit for six months, with permanent prohibition of any cooking or frying operations at the site after the interim period.

Trustees said they will review the draft at their March 10 meeting before taking final action on the conditional use permit extension.